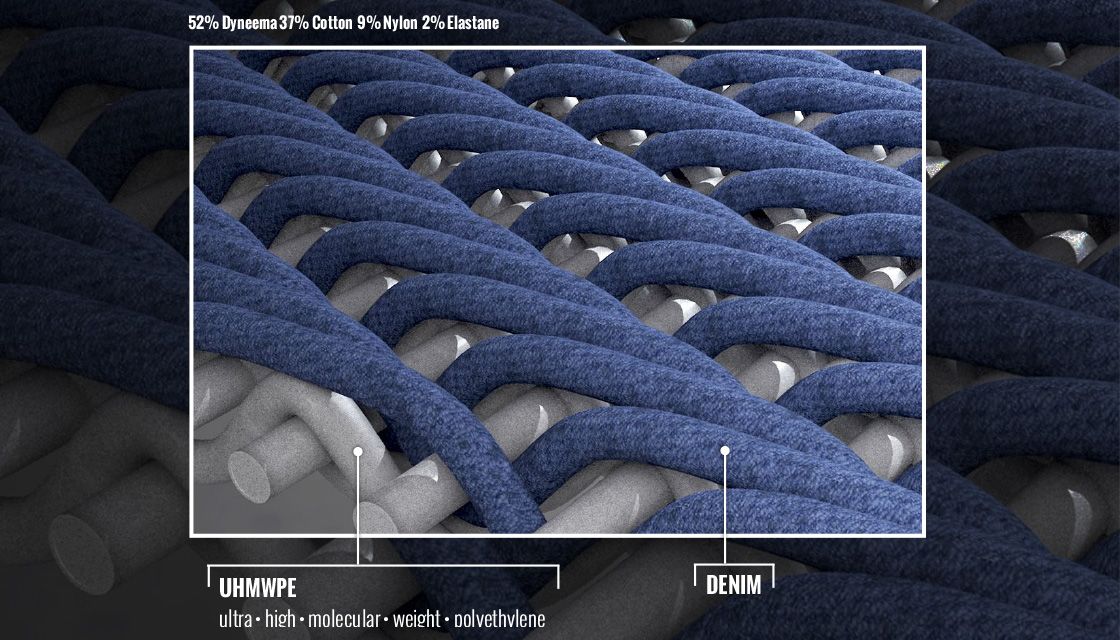

DYNEEMA® material

Dyneema® Denim in majority is a mix of Polyethylene fiber with Cotton. Dyneema® yarn is based on a Ultra High Molecular Weight Polyethylene (UHMWPE) which is manufactured using a special spinning process resulting in a fiber that has an extreme high crystallinity with following properties:

Extreme high tensile strength

Depending on the Dyneema® content in the Denim it will be extremely difficult to tear or break the fabric. It is claimed to be 15 times as strong as steel.

High cut resistance

Denim that contains more than 5 - 10% Dyneema® will have noticeably higher cut resistance compared to regular fabrics.

Abrasion resistance

Using half the amount of Dyneema® improves the abrasion resistance of a single-layer motorcycle denim with aramid by 70%. The like-for-like improvement is 300%.

Chemically inert

Even though Dyneema® itself is chemically inert and therefore resists almost all types of chemicals, it is not recommended to bleach nor dry-clean denim with Dyneema® to prevent quality issues related to the cotton fiber in the denim.

Heat sensitive

Dyneema® has a melting temperature of 140 - 144°C and therefore any exposure to temperatures higher than 130°C, even for short periods (seconds) should be avoided. Hence the recommendation to iron at max 110°C / 230°F and tumble dry at low temperatures.

UHMWPE is odorless, tasteless, and non-toxic, therefore it is widely used in all kinds of industries - bulletproof vests, cut resistant gloves, mooring oil rigs in harbor, fishing nets, biomedical use in orthopedic and cardiovascular implants, sports equipment.